When selecting plumbing systems for residential use, both PEX and copper piping have their advantages. Copper has a century-long track record for durability but can corrode under high water flow and is more prone to leaks at joints. Its environmental impact and higher initial cost are considerations. PEX, on the other hand, is flexible, resistant to corrosion and UV light, and less likely to leak at joints than copper. It's also favored for its resistance to freeze-burst damage in colder regions. Both materials have evolved significantly; PEX was introduced in the 1980s as a flexible alternative to older piping like galvanized steel and asbestos cement, while copper has seen enhancements with more resistant alloys like copper-nickel and copper-zinc. Today's plumbers utilize these materials to meet modern standards for hygiene and efficiency.

Recent advancements have reinforced copper's position as a top choice in plumbing, with new alloys offering improved corrosion resistance and strength. PEX continues to gain favor due to its superior flexibility and durability, with enhancements that increase its resistance to chlorine and environmental factors. Both materials undergo rigorous testing for performance, with copper maintaining its status as a preferred material for plumbers globally due to its reliability and longevity. The ongoing innovation in both PEX and copper piping reflects the dynamic nature of materials science, ensuring that modern plumbing systems are sustainable and meet the demands of contemporary living.

When considering the long-term performance and reliability of plumbing systems within residential settings, the choice between PEX and copper piping often arises. This article delves into the evolving landscape of plumbing technology, highlighting the latest upgrades that enhance durability in both PEX and copper piping solutions. We explore the historical trajectory of these materials, examining how they’ve evolved to meet modern demands. From material enhancements in PEX piping for extended longevity to alloy upgrades in copper for heightened corrosion resistance and strength, we provide a comprehensive analysis. Additionally, we discuss the influence of environmental factors and usage conditions on durability, the importance of adhering to industry standards and certifications, and the insights from professional plumbers on installation and maintenance. Further, we analyze the cost-benefit implications of these upgrades, consider eco-friendly enhancements, and offer guidance on selecting compatible fittings and fixtures. Through real-world case studies, innovative technologies for pipe monitoring, and a look at future trends, this article aims to equip homeowners and plumbers with the knowledge to make informed decisions about their plumbing systems’ durability and sustainability.

- Evaluating Durability: PEX vs Copper Piping in Residential Applications

- The Evolution of Plumbing Systems: A Historical Perspective on PEX and Copper Advancements

- PEX Piping Enhancements: Material Improvements for Enhanced Longevity

- Copper's Continued Relevance: Alloy Upgrades for Corrosion Resistance and Strength

Evaluating Durability: PEX vs Copper Piping in Residential Applications

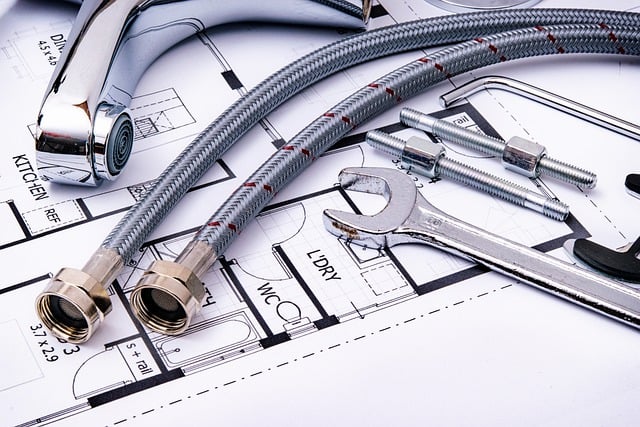

When assessing durability for residential plumbing applications, both PEX and copper piping present unique advantages and considerations. Copper piping, lauded for its longevity, has been a staple in homes for over a century. It is resistant to many corrosive substances and microbial growth, which contributes to its long service life. However, it is susceptible to erosion from high-velocity water and can be more prone to leaks at joints and fittings compared to PEX. The durability of copper pipes also comes with a higher material cost and environmental impact due to the energy-intensive mining and processing required to produce it.

On the other hand, PEX piping has gained popularity in recent years for its flexibility and resistance to corrosion, scaling, and chlorine, which can extend its lifespan when properly installed. PEX is less likely than copper to leak at joints due to its design, often employing fittings that are heat-fused instead of relying on mechanical connections. While PEX has a lower resistance to sunlight and UV exposure compared to copper, it can be protected by simply routing it beneath the foundation or within the walls of the home. Professional plumbers can install PEX with ease, as it is less prone to the freeze-burst phenomenon that can damage copper pipes in colder climates. When considering durability for residential applications, both materials have their merits, and the choice often comes down to a combination of budget, environmental impact, local climate conditions, and the plumber’s expertise in installing either system. Homeowners should weigh these factors carefully when deciding on the piping type that will best serve their home’s needs for years to come.

The Evolution of Plumbing Systems: A Historical Perspective on PEX and Copper Advancements

Over the centuries, plumbing systems have undergone significant transformations, evolving from rudimentary water supply and waste removal methods to sophisticated networks that support modern living standards. The advent of durable materials for piping has been pivotal in this evolution. PEX, or cross-linked polyethylene, and copper have emerged as two leading contenders in the realm of plumbing infrastructure due to their respective advantages.

PEX made its debut in the 1980s and quickly became a popular alternative to traditional materials like galvanized steel and asbestos cement. Its flexible nature allows for easier installation, lessens the likelihood of leaks at joints, and enhances water flow with minimal pressure loss. Copper, on the other hand, has been used in plumbing since the early 20th century, valued for its corrosion resistance and longevity. Advancements in copper piping include improved alloys like copper-nickel and copper-zinc, known as brass or bronze, which are more resistant to corrosion and have extended service lives. Both PEX and copper have their own histories of innovation, with each material’s evolution reflecting the broader technological advancements and changing needs within the plumbing industry. Plumbers today leverage this knowledge to provide homes and businesses with reliable, efficient water delivery systems that cater to the modern world’s demands for clean, safe water and effective waste management.

PEX Piping Enhancements: Material Improvements for Enhanced Longevity

Cross-linked polyethylene, or PEX, piping has gained significant traction in residential and commercial plumbing applications due to its flexibility, durability, and ease of installation. Recent advancements in PEX material science have further enhanced its longevity, making it an even more robust alternative to traditional copper piping. Manufacturers have introduced enhanced formulations that incorporate improved cross-linking technologies, which not only bolster the piping’s resistance to a range of environmental factors but also significantly extend its lifespan. These upgrades ensure that PEX pipes are less susceptible to issues like degradation from chlorine in water, making them an ideal choice for plumbers and property owners seeking reliability and longevity in their plumbing systems. The latest iterations of PEX piping undergo rigorous testing to withstand higher temperatures and pressures, ensuring that they remain a viable option for both hot and cold water applications. This commitment to innovation means that PEX piping is becoming increasingly sophisticated, offering long-term performance benefits and reducing the need for frequent repairs or replacements, which is a boon for plumbers and homeowners alike.

Copper's Continued Relevance: Alloy Upgrades for Corrosion Resistance and Strength

Copper piping has long been a staple in plumbing systems due to its superior strength, malleability, and conductive properties. Despite the emergence of alternative materials like PEX, copper remains a relevant choice for many applications because of its reliability and longevity. Recent advancements in copper alloy technology have further solidified its position in the plumbing industry. These upgrades enhance corrosion resistance and provide greater strength without compromising the material’s workability or its ability to withstand extreme temperatures. For instance, modern copper alloys like brass and bronze exhibit significantly improved performance over traditional copper in harsh environments and water conditions that can lead to corrosion. Plumbers across the globe recognize these benefits, as they result in fewer maintenance calls and longer-lasting infrastructure. This makes copper an even more attractive option for both new installations and retrofitting existing systems, ensuring that the pipes can deliver clean, safe water for decades to come. The integration of these alloy upgrades underscores a commitment to sustainability and reliability in plumbing applications, reflecting the continuous evolution of materials science to meet modern demands.

In concluding our exploration of plumbing infrastructure, it is evident that both PEX and copper piping have undergone significant advancements to enhance their durability in residential applications. While copper continues to be a reliable option due to its inherent strength and corrosion resistance, innovations in PEX piping have led to material improvements that promise extended longevity and better performance. Homeowners and plumbers alike can benefit from these upgrades, ensuring a more efficient and sustainable water delivery system for years to come. The historical perspective provided underscores the evolution of plumbing systems, highlighting the importance of staying informed about the latest advancements in this critical aspect of home maintenance.